Environment

The observation is simple and shared, we do not have a planet B. The environment plays an integral part in the problems manufacturers face. It is no longer possible to produce, design, and sell products without thinking of the impact they may have on the environment.

Definox is technically involved in designing more sustainable products and committed to a global reduction in consumption. The high standards of its know-how contribute to developing its industrial practices in the sense of a collective awareness.

HOW DOES DEFINOX SUPPORT MANUFACTURERS ON ENVIRONMENTAL ISSUES?

RESPONSIBLE DESIGN CHOICES

- Interchangeability of sub-assemblies and components.

- Encouraging the use of locally produced components.

- Integrating environmental criteria in product design.

SUSTAINABILITY OF EQUIPEMENT

- Sustainable designs of Definox products.

- Equipment lifespan of over 40 years for an optimal and economical use.

- On demand components, well beyond the sale of standard replacement parts.

MAINTENABILITY OF COMPONENTS

- Definox products are entirely maintainable.

- Components replaced on demand.

- Reparation of valves used in rotation so as not to disrupt production lines.

- Retrofitting of valve assemblies.

MODERNIZATION OF INFRASCTRUCTURES

- Renewal of the machine park.

- Optimization of the pickling station to diminish energy consumption.

- Project of recuperating heat generated by the machines to be reused in the process.

OPTIMIZATION OF RESOURCES

The rise in consumer demands, the volatility of raw material quality and cost increases are leading manufacturers to produce better and more sustainably.

The Philosophy of up-cycling

Preserving our resources includes fighting against obsolescence. The oldest valves still have spare parts available, beyond the classic 10-year period, allowing you to upgrade your park at the fairest environmental and economical cost.

- Our valves are 100% repairable using standard maintenance tools.

- Pneumatic actuators can be completely disassembled in order to replace only the necessary parts.

- We integrate retro compatibility in all of our new development projects.

Recyclability

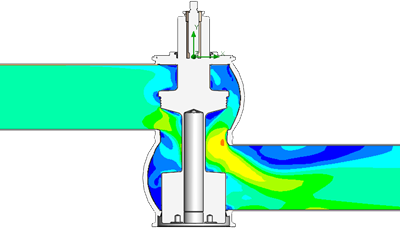

Our design office uses digital simulation to make the first prototypes, optimizing the use of raw materials and energy. We aim for reliable, robust designs that significantly reduce the frequency of part replacement. The geometry and materials used offer durability and waste reduction throughout the life cycle of the equipment

Continuous improvement

Definox and its SORIO technology help you to meet the challenge of sustainability and performance. With continuous improvement we accompany you in the optimization of your resources.

TESTIMONY

Our valves are not disposable, they are repairable. We are the antithesis of planned obsolescence. In the Definox mind set, keep everything and throw nothing away !

COMMITMENTS BEYOND THE PRODUCT

AMBITION 2025

- Reduce our energy consumption.

- Off set our carbon emissions.

- Integrate more and more environmental criteria into our product designs.

- Encourage local production.

MOVING TO 100% RENEWABLE ENERGY

Our French energy provider buys electricity from renewable sources : Wind turbines, solar panels, hydro-electric dams.

WASTE & PACKAGING

- Products that can’t be recycled are treated again.

- Hazardous waste is stored to be treated off site.

- Recyclable Packing paper is recycled.

- Cardboard, wood,plastic, all of our materials are recycled.

WATER CONSUMPTION IN 3 YEARS

COLLECTIVE COMMITMENTS

- Multiplication of local initiatives and solidarity (the climate fresque).

- Encourage soft mobility (indemnity for kilometers).

- Individual contribution for the collective.

Environment : news

- The approach DNA : true customer support

Several months ago, Definox decided to speak about the major concerns of its customers. Today, these words have taken form with a new section on the website, full of new content and the latest news….

Several months ago, Definox decided to speak about the major concerns of its customers. Today, these words have taken form with a new section on the website, full of new content and the latest news….