Decarbonisation journey: Definox committed to its environmental transition

While Definox has been working on its QSE issues for many years, 2023 marks the start of a decarbonisation journey for the company. Definox’s management committee is about to take part in a day devoted to the ecological transition and understanding the environmental issues associated with decarbonisation. With this in mind, we spoke to Marie Jourdain, QSE Manager at Definox since 2011. Interview.

Could you describe your role at definox?

“As QSE Manager (Quality, Safety and Environment), the first part of my work at Definox was mainly quality-oriented. I had to put the quality management system back in place to improve internal processes. After that, I focused mainly on safety, followed by the introduction of preventive measures. These are processes designed for the long term because you have to keep renewing yourself in each of the 3 areas.

For the past two years, Definox has been tackling the environmental side of QSE issues head on. Everything to do with scopes 1 and 2 in a carbon footprint was very accessible for us: managing our energy consumption (electricity and gas), water and waste management. Our consumption is monitored on a month-by-month basis to ensure that there are no anomalies.

For example, we have introduced a new form of waste recycling using SRF (Solid Recovered Fuel) recycling containers in collaboration with our service provider BRANGEON Recyclage. Instead of being landfilled for lack of an outlet, this waste is cut up and burnt in cement works to produce energy.

Today, our objective with the decarbonisation programme led by Alter-Eco and Mission Change is to accelerate our ecological transition. To achieve this, we are working towards obtaining our carbon footprint by the end of 2023, covering all scopes. We will then need to draw up an initial action plan, focusing in particular on scope 3, which has the highest emissions.”

If scopes 1 and 2 concern consumption, as we said, what exactly does scope 3 entail?

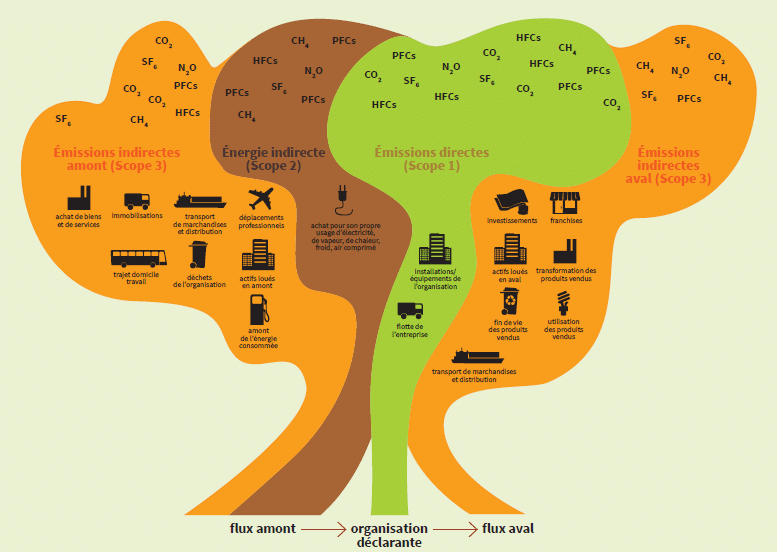

“You’re right to point this out. Scope 1 covers direct greenhouse gas emissions, scope 2 indirect emissions linked to energy consumption and scope 3 covers all other indirect emissions. For Definox, scope 3 includes a much wider perimeter, from supplier to customer. For example, it covers the freight and transport of our goods, employee travel, the end-of-life of our products at the customer’s site, and all other inputs.”

into 3 categories known as “scope 1-2 and 3”

Source Ademe

how does definox ensure compliance with the quality, safety, and environmental standards applicable to your industrial sector?

“From a macro point of view, we have indicators and a two-year strategy that gives us very clear objectives in each of the QSE areas. Next, a regulatory and technological watch should enable us to meet all the requirements of our business.

The concrete objective for our company is to achieve carbon neutrality by 2030. It is an ambitious goal. In practical terms, this means reducing our ‘consumption’, measuring our carbon impact and reducing the environmental impact of our products, services and processes.”

WHAT ARE THE MAIN ENVIRONMENTAL ISSUES IN YOUR PRODUCTION CHAIN?

“From a production point of view, the challenges lie in reducing our consumption – of energy, materials, etc. – and improving our processes, in particular by turning to the eco-design of our products. Our basic product is environmentally friendly. Our products have been installed on our customers’ premises for decades. These are not disposable products, and we keep spare parts for a very long time.

Our issues are primarily consumption issues for our site and waste production. The message I’m trying to get across is that “the best waste is the waste that we don’t produce, that doesn’t exist”, but it’s complicated. Often the answer is to say that we recycle well. So yes, we do recycle, but now we have to reduce.”

HOW DOES DEFINOX INTEGRATE ENVIRONMENTAL SUSTAINABILITY INTO ITS PRODUCTION AND WASTE MANAGEMENT PROCESSES?

“In our production processes, we monitor and control with the aim of not increasing our consumption or waste production.

We regularly renew our machinery, which is a real factor in reducing consumption. New processes and new machines should enable us to reduce our consumption. What’s new is the monitoring of our CO2 with the carbon footprint.”

WHAT KEY PERFORMANCE INDICATORS (KPIs) do you use to measure and continually improve your environmental performance?

“We have several key indicators that enable us to measure our environmental performance:

- Percentage of waste recycled

- CO2 emissions

- Energy consumption.

- Water consumption.

- EcoVadis rating (an environmental rating that can be updated and consulted by customers)”.

led by Arnaud Marec from Agence 21-22

coming back to the project to launch the decarbonisation pathway. can you tell me a little about the context, the need, and the prospects for this initiative?

“Two years ago, we produced climate frescoes with all our employees. In 2022, more than 80 people took part. The aim is to provide expertise on climate issues and to develop a shared vision and vocabulary. Knowing what we’re talking about when we talk about CO2, when we talk about environmental transition, etc. Definox is now taking things to the next level.

At a local level, we were given an opportunity to get involved by the Communauté de communes de Clisson and Alter-Eco, a decarbonisation programme deployed by the Mission Change association with a number of local businesses. It gives us a foothold in our local network.”

what programmes or initiatives have you put in place to raise awareness and educate your employees about the importance of protecting the environment in their day-to-day work?

“Following the various Climate Frescoes, we put in place a concrete action plan based on employees’ proposals. 32 actions were identified among the proposals, 16 of which were already under way.

There were actions already in place, such as encouraging the use of soft mobility, the staff car hire policy, and giving priority to video over travel.

There are actions underway for 2023, such as better recycling of packaging, better management of SRF waste, and encouraging the elimination of plastic bags in favour of kraft paper.

Other actions to be studied include recycling hard plastics and local production to avoid unnecessary transport of goods. The long-term aim is to move away from air travel to rail and sea. With China, rail transport is becoming increasingly important.”

Do you have any other points to make about the environment?

“As far as the environment is concerned, I’d like to mention all the public and semi-public actions that have been taken. We should soon be receiving assistance from ADEME. Institutional support helps speed up the process, and that’s a good thing!

Definox is a 6-step, 6-month, tailor-made programme combining individual support and time for collective intelligence in conjunction with the local and regional ecosystem:

- Diagnose our current model in the light of the challenges of planetary limits (climate, material resources, biodiversity, etc.).

- Receive support in changing or transforming the business model to one that is compatible with the planet’s limits.

- Establish links with the local ecosystem.

Let me conclude by saying this. Definox products are renowned for their reliability and durability. Embarking on a decarbonisation journey means anchoring our product and processes in the long term and working even more closely with our users, but also with our suppliers and employees.”