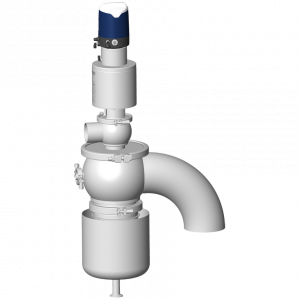

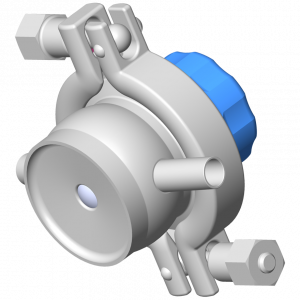

DCX3 FC tank bottom single sealing shut-off valve

Fitted with a mass-flange, the DCX3 tank bottom valve is used for isolating the tank from the process during emptying or filling of the tanks.

If you are looking for documentation, go to our Document Library

Fitted with a mass-flange, the DCX3 tank bottom valve is used for isolating the tank from the process during emptying or filling of the tanks.

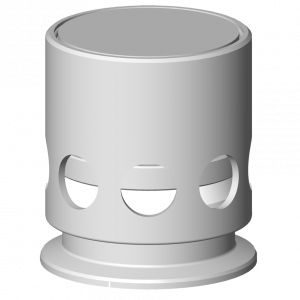

The autonomous sanitary vent AVX1 ensures protection against vacuum and overpressure of inert tanks (sterile air or neutral gas).

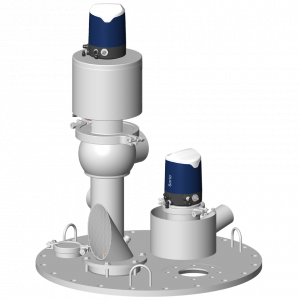

The tank top module from Definox equip liquid storage tanks. They manage the CO2 given off from the liquid stored in the tank. Thèse modules adapt to the geometry of the tank and have diverse accessories depending on the type of product.

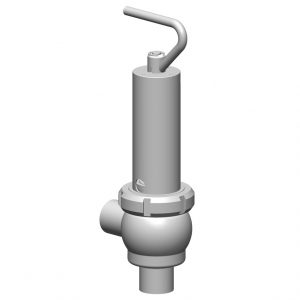

The single sealing adjustable relief valve combines safety and accuracy thanks to its finetuning system. A predefined pressure relieves the main circuit protecting certain devises or circuits.

The DCX3 additional air valve relieves pressure from the main circuit using a predefined pressure, protecting components and peripheral circuits.

A non return valve (or check valve) allows for the control of the direction that the fluid circulates. This system lets the fluid pass through

A relief valve responds to overpressure on the lines. Different springs can cover a pressure span of between 0 to 13 bars.

The vacuum pressure relief valve is a tank protection device used during the pressure and vacuum phases. The valve exhaust is not channeled.

In order to facilitate powder sampling from drying silos, Definox offers a volumetric sampling valve. The powder flow is gravity discharged. It allows for repeatability of the sample taken from a given volume or frequency.

The sampling diaphragm valve DMX PE and DMAX PE integrate a physical barrier between the interior of the valve and the external environment. The sample is taken under optimum aseptic conditions.