Expertise

Optimization of costs is a central issue for manufacturers. How to control, reduce and improve processes to be profitable but above all performant. Calculating the TCO makes it possible to take into account the total costs needed and thus be as close as possible to the economic reality. Definox makes its expertise and know-how available to its customers and partners.

How does Definox help manufacturers control TCO ?

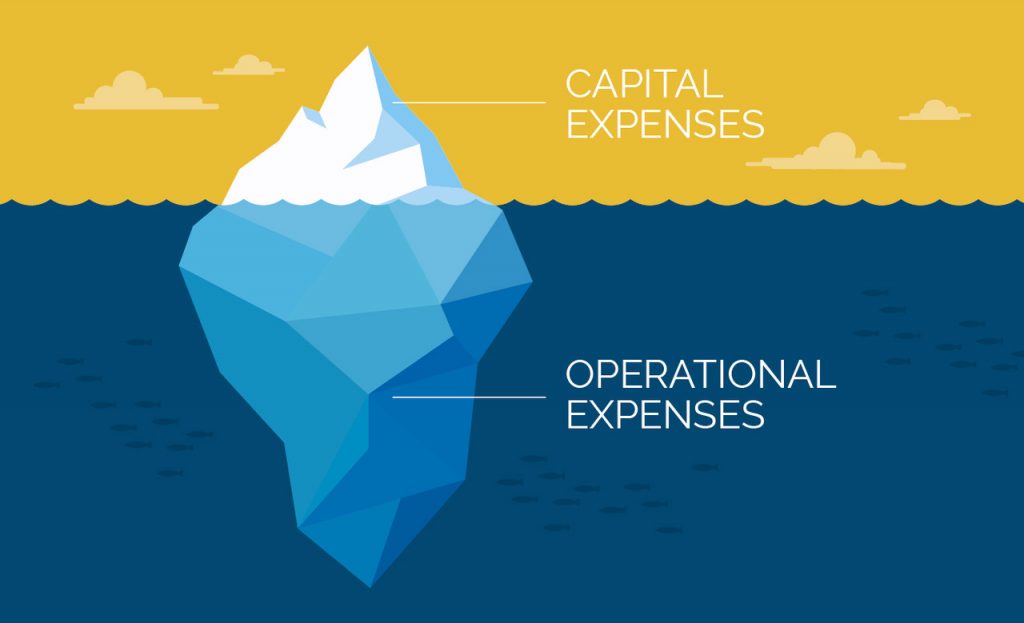

TCO : What is it ?

Total Cost of Ownership is an estimation of the purchase value of a product throughout its life cycle. Indeed, a product is not worth just the purchase price or its action. Additional costs should be considered in order to obtain its real amount.

Reparability : Acting on product maintainability

Definox prescribes to the concept of entirely maintainable valves. It guides the design of our solutions and influences the choices of industrial processes for making components that are in contact with process flows. This principle positively impacts 2 aspects.

- A TCO the most advantageous on the market with a fair repair cost (30% maximum of the price of the valve.)

- Spread out interventions and fast maintenance operations thanks to the valve design (easy dismantling, maintenance recommended every 5 years for an actuator, in depending on the type of flow process, cleaning and servicing conditions.)

Residual value: Acting on the product life span

- Thanks to the interchangeability of their components, Definox is able to offer you advantageous exclusive service. This contributes to a long-life span for your equipment.

- The Reparation by rotation ensures expert management of your valves. Your equipment is refurbished to new condition in our workshops, without interruptions to production.

- Retrofitting the valves and sets of installed valves allows you to benefit from the latest technology and guarantees an optimized operation of your processes. The new generation of the Sorio control top adapts to all generations of Definox valves, as well as other valves on the market.

Definox positions itself on products to maintain the most efficient TCO possible. Cost control is an essential issue because at Definox a valve is purchased for around ten years.

Productivity : Acting on the availability of production lines

- The design of our valves integrates a quantity of seals limited, reducing the breakdown risks and allowing shorter maintenance operations

- Innovation at the service of production, with the Sorio control box and its “warning” function that warns of activity outside of the valve tolerance

Added value service: Acting on the transfer of knowledge

- Gain autonomy and ensure the safety of your teams during interventions, through our practical and theoretical training.

- Benefit from personalized support at each stage of your projects.

- The augmented reality mobile phone application “id” saves you time and allows the valve and valve parts to be easily identified.

Energy savings : Acting on energy consumption

- The extent of the ranges in terms of technology and diameters allows for a rational choice.(flow coefficient (KV/CV))

- The new generation of mixproof valves VEOX allows for a reduction of 30% in CIP loss during plug lift.

- The Veox valve has the lowest number of seals on the market, it only takes 30 minutes to completely put back together. Maintenance times and costs are reduced.

- The design of our pigging systems offers a low friction coefficient while recovering the maximum of the scraped product. Using the DN51 SMS mono-block scraper over a 100-kilometer course will recover 97.5 of the scraped product.

Smart design : Acting on product design

- The VEOX range of mix-proof valves have a radial seal with a stainless-steel insert as standard. This patented technology contributes to better seal stability and limits dilation whilst improving temperature and pressure performance. Its life span is longer, and intervention times are reduced

- The valve variants offered as standard (VEOX multi-size bodied or VEOX 3 bodies) allow to optimize the number of valves needed on a line depending on production process issues.

DEFINOX TECHNOLOGY

The machining, lathing, and welding techniques used by Definox in the making of our valves give strategic components in contact with fluids a high level of finish and quality, complying with the process requirements.

- Machining the valve bodies and plugs from solid stainless steel guarantees the parts have no liquid retention zones. This procedure and the body thickness between 6 to 7 mm contribute to the high resistance to mechanical and thermal deformations.

- Milling and lathing operations offer a large flexibility for adapting outlet pipes. Numerous configurations are thus made possible.

- The annealing heat treatment provides unequaled resistance to corrosion.

- The quality of the welding (carried out by TIG certified welders), complies with hygienic standards and demands. The welds guarantee a solid geometry and a resistance of the mechanically welded assemblies.

- Tribofinishing makes it possible to have smooth surfaces which reinforce the in-line cleanability required in sanitary processes.

The advantages of TCO

IMPROVE

the financial performance of the production lines

CALCULATE

the costs in an objective and global manner

ANTICIPATE

costs over the entire life cycle

CONTROL

the availability of the production lines